After gaining access to efficient turbine blades, the selection of a generator follows.

Alternately, after gaining some experience, the technique for turbine blade manufacture is chosen depending on the availability of suitable generators that;

- function in weathering conditions

- have known power output

- have a rated operating velocity

(RPM, speed in revolutions per minute).

Alternately, after gaining some experience, the technique for turbine blade manufacture is chosen depending on the availability of suitable generators that;

- function in weathering conditions

- have known power output

- have a rated operating velocity

(RPM, speed in revolutions per minute).

The power available for production using your customised turbine specifications will give a unique profile for power output with increasing wind speed in each individual case.

The measured power curve for your generators RPM should closely match the effective blade power at the optimal TSR.

During testing, we adjust the TSR at each wind speed by changing the load resistance to measure the blade power vs TSR.

During testing, we adjust the TSR at each wind speed by changing the load resistance to measure the blade power vs TSR.

In areas where the wind is intermittent, a small amount of power can be used to start up the generator to reach the operating TSR over a shorter time period than normally taken using the force of wind alone. This allows power to be converted as quickly as possible after the wind has reached the speed required to operate the turbine for power generation.

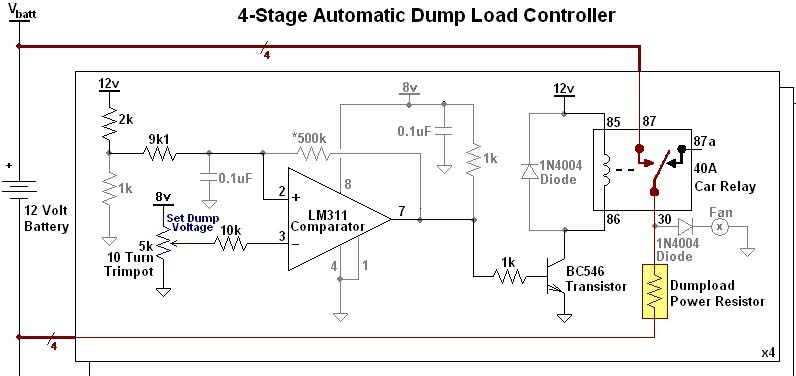

Electronic means of adjusting or stopping the wind turbine operation in high wind speed include a circuit system for braking. This is needed if the generator begins to produce overvoltage. Mechanical methods to avoid operation during high wind involve mechanical furling systems.

The generator 'voltage per RPM' will determine the load that can be used to draw current from the entire generating system.

A low resistance load will temporarily draw high current at the moment that the load is applied. A rapid reduction in voltage occurs until the generators RPM is moving current that will convert the same power from the blades, but at a new RPM.

If this new generator RPM causes the blades TSR to fall below the optimal range for producing 'lift', efficiency is greatly reduced. In this case, the generator speed is insufficient to produce power, causing the turbine to 'stall'.

If this new generator RPM causes the blades TSR to fall below the optimal range for producing 'lift', efficiency is greatly reduced. In this case, the generator speed is insufficient to produce power, causing the turbine to 'stall'.

If a load resistor is present in the generating circuit during 'start-up' the turbine will fail to start, even in high wind speed. The blades have not yet reached the optimum TSR and high efficiency needed to maintain power production.

Rectifying circuits divert current into flow into the battery after a certain RPM and voltage have been reached. Below this speed, the turbine spins freely (until the generator voltage exceeds the battery voltage).

This circuitry is used to divert the current away from the battery input and into a dumpload to protect the battery and other circuitry (inverter and other appliances) from overvoltage.

This circuitry is used to divert the current away from the battery input and into a dumpload to protect the battery and other circuitry (inverter and other appliances) from overvoltage.

Matching Blades and Generators