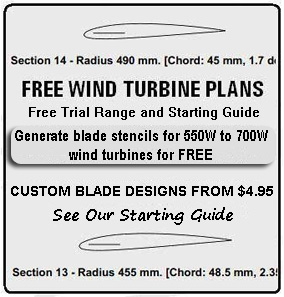

FREE

Sample chord

sections can be

generated for

blades between

0.70 to 0.80 m (550

Watts to 710 Watts).

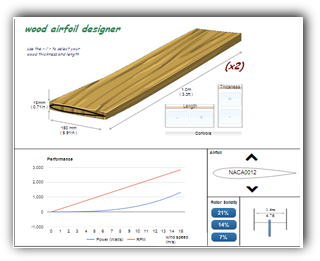

Design custom blades for your generator and calculate power output at each wind speed.

Frequently asked questions about plan orders, blade design, electrical work and generator matching can be found on our Q&A pages.

Welcome to Warlock Engineering

NEWS & UPDATES

Free plans for 500 W blades

with each purchase.

Articles in PDF format

Design, simulation and construction of a

Loss factor measurements for organic

solvents at frequencies 0.1 - 40.0 GHz.

Wind Turbine Articles in PDF |

| BLADES: • 1.4 Metre Diameter 3-Blade Wind Turbine Construction [PDF] • 10 kW (13 m/s), 5 Metre Diameter Carbon Fibre Blades for Wind Turbine [PDF] |

| BLADES AND GENERATOR: • 1.8 Metre Diameter Carbon Fibre Wind Turbine Blades and Generator [PDF] |

| GENERATOR: • 10 kW, 15 Phase Axial Flux Pancake Generator for 2-Blade Wind Turbine [PDF] |

Welcome and thanks for visiting our site. Access free design software or read documentation on wind turbines or other research projects. Your support allows us to provide more free online resources, tools and content for the diy community. Find some interesting projects along with popular web content using the links on this page or from the menu bar. .

Background summary of selected projects

Wind turbine technology has an identified limit for the efficiency in which kinetic energy can be converted into electricity, described mathematically as the 'Betz Limit' of ~59%.

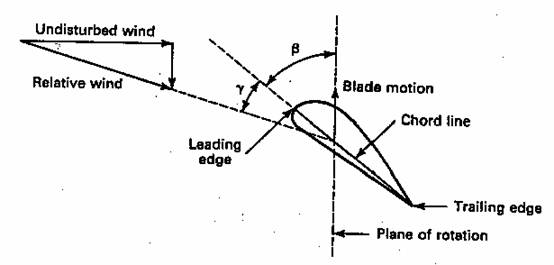

Slow moving 'windmills' have blades that move due to air resistance (drag), although modern wind turbines use knowledge about aerodynamics to incorporate an airfoil shape, providing 'lift' force on the blade.

Slow moving 'windmills' have blades that move due to air resistance (drag), although modern wind turbines use knowledge about aerodynamics to incorporate an airfoil shape, providing 'lift' force on the blade.

Software for the designing wind turbines of specified size, speed and blade number, remains a focus of our research.

Our wind turbine calculations were established in the original 'Blade Calculator' for Windows 95 by using the experimental measurements obtained during the controlled testing of completed turbine builds.

Our wind turbine calculations were established in the original 'Blade Calculator' for Windows 95 by using the experimental measurements obtained during the controlled testing of completed turbine builds.

Wind Energy Technology

Wind Energy Software

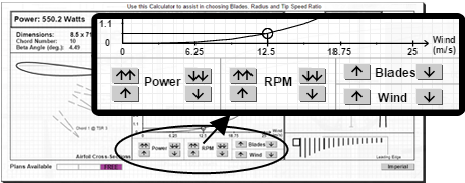

Online Blade Calculator Software

Use our online blade calculator to design wind turbine blades for your generator.

The generators specified rotational speed (RPM) needs to closely match the turbines RPM at operating wind speeds to produce the power and voltage rated on the generators plate.

The power that can be converted into electricity from wind energy is proportional to the radius. The average windspeed is adjusted to suit the location and can be useful to approximate the increase in blade radius required for low wind speed.

Modifying the blades shape will change the ratio between the tip speed of the blade and incoming wind speed (TSR); lesser number of blades can spin at a higher TSR.

Two bladed turbines operate in a TSR range between 8 and 10, with 3 bladed turbines spinning at a TSR between 6 to 7.

Crypto

Make

Purchases

Using

Purchases

Using

Enable Ads for www.warlock.com.au

Background summary of selected projects

SPONSORED ADVERTISEMENT

Electrical Circuit Design

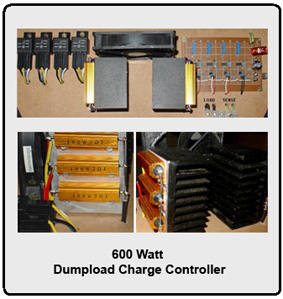

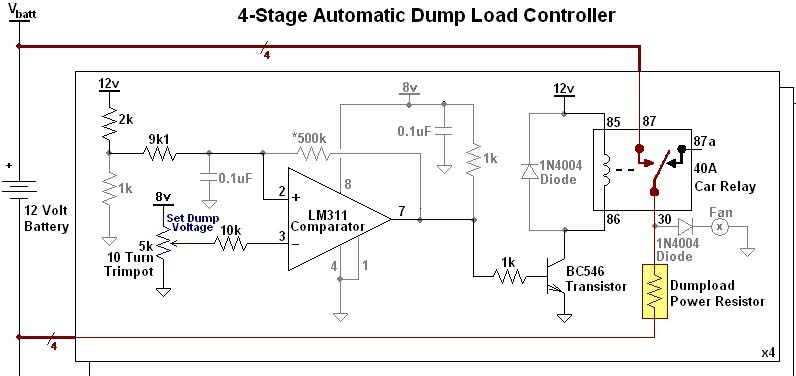

Power output from the turbines electrical generator will change depending on the RPM. With small domestic wind turbines the excess power needs to be managed.

Rapid increases of voltage (and current) due to wind gusts can be regulated using the dumpload electronic circuitry. This protects the system output from overvoltage and excess energy is expended in a 'dumpload' resistor as heat.

Wind Turbine Blade Manufacture

Manufacture of wind turbine blades involves making a choice of materials (wood, plastic or composite) and this can determine your working techniques.

The weight of the final blade set should be considered. Blade weight and radius contribute towards a combination of stresses on the generator and hub. Heavy objects also require more energy to reach high velocity in the force of the wind.

Fibreglass Blades

Construction methods using plastic composite materials allow the blade weight to be significantly reduced leading to faster start-up.

The advantages of using plastic composites to produce blades and moulds includes improvements in accuracy for blades that taper and twist. The increased strength and rigidity of materials maintain blade shape at high velocity and throughout the weathering process.

The construction accuracy of airfoil dimensions (including angle and positioning along the blade) is only limited by ones personal experience and technique. Plastic composites can be more amendable to address these deficiencies.

Enable Ads for www.warlock.com.au

Background summary of selected projects

SPONSORED ADVERTISEMENT

Matching Blades and Generators

Heating by Microwave Energy

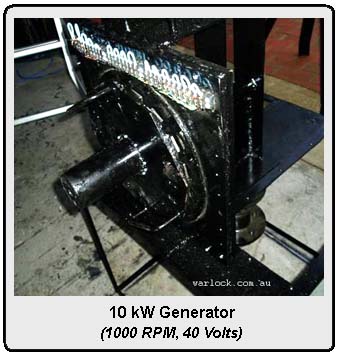

Suitable generators function in weathering conditions, have known power output and rated operating velocity (RPM).

Your customised turbine specifications will give a unique profile for power output with increasing wind speed.

The measured power curve for your generators RPM should closely match the effective blade power at the optimal TSR.

Electronic means of adjusting or stopping the wind turbine operation in high wind speed include a circuit system for braking. This is needed if the generator begins to produce overvoltage.

The generator 'voltage per RPM' will determine the load that can be used to draw current from the entire generating system. The blades must reach the optimum TSR and high efficiency needed to maintain power production.

Details of the microwave reactor design are given along with the 2.45 GHz RF simulation used to assess the expected leakage from the reaction chamber.

The use of microwave radiation to supply thermal energy for chemical reactions has been studied, along with reactor vessel design.

Microwave absorption of organic reagents and solvents with different functional groups have been measured and graphed over a range of radio frequencies (RF).

Dielectric loss measurements are used to compare materials at wavelengths other than the commercial 2.45 GHz frequency

POPULAR PAGES

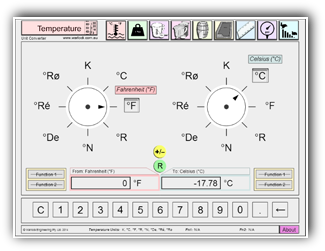

Welcome to Warlock Engineering's free Web-Applications *** Free Software, Tools & Apps. ***

Welcome to Warlock Engineering's free Web-Applications *** Free Software, Tools & Apps. ***