Back to information about.....

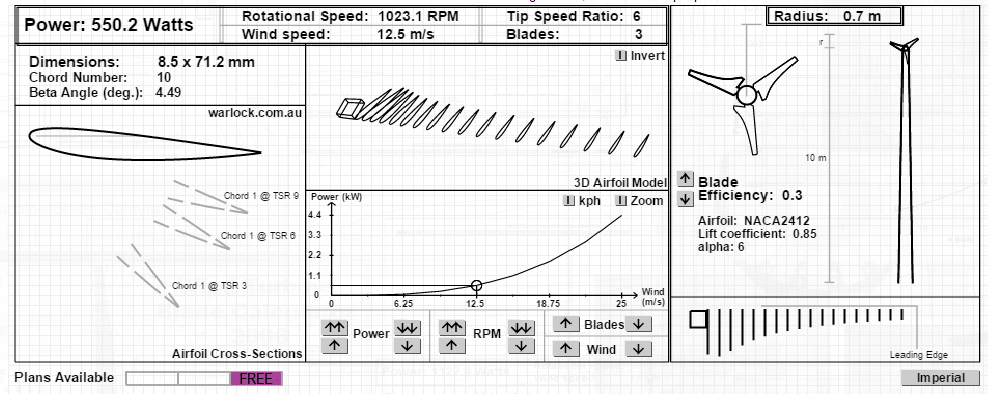

Turbine Blade Calculator Software

Wooden blades without twist or taper are fast to manufacture without a large investment in prior planning. Custom taper and twist vs length are possible to construct using wood, although the closeness to the ideal accuracy in the final product can be difficult to assess. Changes in blade shape, caused by deformation of the wood grain during further moisture losses are made worse by exposure to heat and weather. Inconsistent wood grain properties make hub attachment a larger concern than is immediately apparent, as the wood is smaller at this point and holds both the blade weight and force during operation. Turbines with a large number of blades or high TSR can be too thin to manufacture from wood, requiring additional coating in fibreglass composites

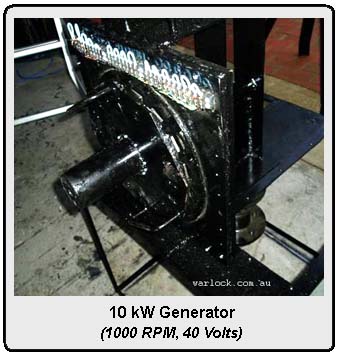

After gaining access to efficient turbine blades, the selection of a generator follows. Alternately, after gaining some experience, the technique for turbine blade manufacture is chosen depending on the availability of suitable generators that function in weathering conditions, have known power output and rated operating velocity (RPM, speed in revolutions per minute).

The power available for production using your customised turbine specifications will give a unique profile for power output with increasing wind speed in each individual case.

The power available for production using your customised turbine specifications will give a unique profile for power output with increasing wind speed in each individual case.

In areas where the wind is intermittent, a small amount of power can be used to start up the generator to reach the operating TSR over a shorter time period than normally taken using the force of the wind alone. This allows power to be converted as quickly as possible after the wind has reached the speed required to operate the turbine for power generation.

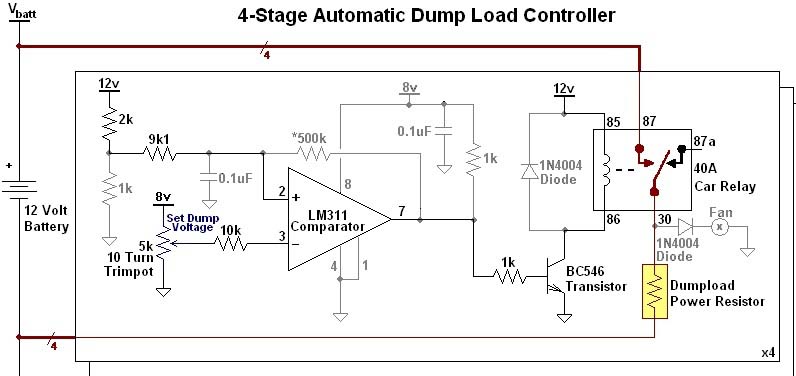

Electronic means of adjusting or stopping the wind turbine operation in high wind speed include a circuit system for braking. This is needed if the generator begins to produce overvoltage. Mechanical methods to avoid operation during high wind involve mechanical furling systems.

Electronic means of adjusting or stopping the wind turbine operation in high wind speed include a circuit system for braking. This is needed if the generator begins to produce overvoltage. Mechanical methods to avoid operation during high wind involve mechanical furling systems.

The measured power curve for your generators RPM should closely match the effective blade power at the optimal TSR. During testing, we adjust the TSR at each wind speed by changing the load resistance to measure the blade power vs TSR.

Designs that involve rectifying circuits allow current to flow into the battery after a certain RPM and voltage are reached. The turbine spins freely until the generator voltage exceeds the battery voltage. Circuitry is used to divert the current away from the battery input and into the dumpload to protect the battery and other circuitry (inverter and other appliances) from overvoltage.

Organic chemicals containing 'non-metal' atoms are joined by atomic bonds. Vibrations in all directions in space occur if the molecule encounters thermal energy (heat). When the chemical structure contains differences in electron density or 'polarity', the absorbtion of microwave energy occur. Microwave absorption of organic reagents and solvents are graphed over a range of radio frequencies (RF).

Details of the microwave reactor design are given along with the 2.45 GHz RF simulation used to assess the expected leakage from the reaction chamber.

ADVERTISEMENT

Frequently asked questions about plan orders, blade design, electrical work and generator matching can be found on our Q&A pages.

Although fibreglass composites have superior strength, the cost effectiveness of wood carved blades currently can't be matched, along with the ease of access to resources. Appropriate wood types can be used to build wind turbine blades if the correct grain and drying process has been followed, as this provides some confidence that the finished product will be robust.

The accuracy of airfoil dimensions and angle at each position along the blade is limited by experience and technique during construction. Plastic composite materials are more amendable in case of errors and the accuracy can be monitored and corrected at many stages throughout construction

The generator 'voltage per RPM' will determine the load that can be used to draw current from the entire generating system. Using a low resistance load will temporarily draw high current at the moment that the load is applied. A rapid reduction in voltage occurs until the generators RPM is moving current that will convert the same power from the blades, but at a new RPM. If this new generator RPM causes the blades TSR to fall below the optimal range for producing 'lift', efficiency is greatly reduced. In this case, the generator speed is insufficient to produce power, causing the turbine to 'stall'. If a load resistor is present in the generating circuit during 'start-up', the turbine will fail to start, even in high wind speed. The blades have not yet reached the optimum TSR for high efficiency and would not maintain power production.

Matching Blades and Generators:

Heating by Microwave Energy:

Microwave heating has common household and industrial uses, although its practical application is both facilitated and limited by the interaction with materials at a molecular or atomic scale. The use of microwave radiation to supply thermal energy for chemical reactions has been studied, along with reactor vessel design. Measurements for the interaction between microwave radiation and organic functional groups have been conducted at wavelengths other than that the standard commercial 2.45 GHz operating frequency. Dielectric loss measurements are used to compare materials.

Previous

Page

Page