The wind turbine was bolted to a trailer and rpm, voltage and tsr was measured by connecting the generator to a very high power multi-tap resistor. The turbine was allowed to speed up to an open circuit voltage of 65 V (666 rpm) before the resistor load was connected.

Figure 11. Turbine testing

Measurement of results from the wind turbine

Note: Our method of turbine testing generated turbulent wind, affecting efficiency. The results should be used as a guide only

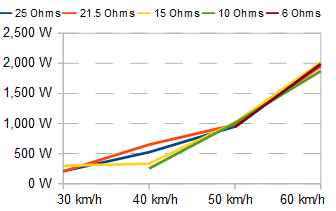

Rs is the resistance of the generator windings plus the power cable; 5.75 ohms

Rl is the resistance of the load; 6.6, 10, 15, 21.5 and 25 ohms

Once the blades have been characterized,

a new generator will be designed.

a new generator will be designed.

Power generated by the blades was calculated by dividing measured power by the efficiency of the generator. The following method is used to calculate the power generated by the blades;

Voltage across the resistor load was measured (Vl),

Vs = Vl x [(Rs + Rl) / Rl ]

Power produced by blades and lost in the generator, power cable and resistor load is given by;

P = V2/R

P = Vs2 / (Rs+Rl)

Results from the turbine test are tabulated below;

Testing the wind turbine

Total cost of the wind turbine

System cost (AUD)

Induction motor $15

Magnets $80

Moulds $72

Two Blades $14

Total cost $181

Conclusion

Continue to summaries about.....

500 W Kevlar Blade Construction

Frequently asked questions about plan orders, blade design, electrical work and generator matching can be found on our Q&A pages.

Previous

Page

Page

Related Articles

Vs

Rs

Rl

Vl

30 km/h

40 km/h

50 km/h

60 km/h

40 km/h

50 km/h

60 km/h

30 km/h

40 km/h

50 km/h

60 km/h

40 km/h

50 km/h

60 km/h

30 km/h

40 km/h

50 km/h

60 km/h

40 km/h

50 km/h

60 km/h

30 km/h

40 km/h

50 km/h

60 km/h

40 km/h

50 km/h

60 km/h

30 km/h

40 km/h

50 km/h

60 km/h

40 km/h

50 km/h

60 km/h

Rotational Speed (RPM)

Power (Watts)

Blade Efficiency

Tip Speed (km/h)

Tip Speed Ratio (TSR)

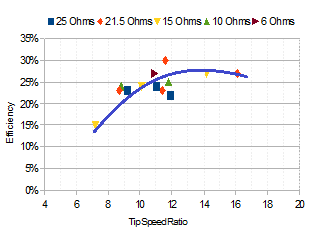

Figure 12. Efficiency vs TSR

Figure 13. Measured Power

Power (Watts) vs Speed (km/h)

Power (Watts) vs Speed (km/h)

The carbon fibre blades maintained peak efficiency of 27% for all Tip Speed Ratios (TSR) between 10:1 and 14:1, The maximum power generated was 2.0 kW at 60 km/h wind speed.

By comparison, the typical tip speed ratio for wood carved blades is 7:1. Although they are cheaper to procuce, wood blades rotate at half the RPM reducing generators power output to 25%.

25Ω

820

1302

1753

820

1302

1753

21.5Ω

766

1363

1676

2365

766

1363

1676

2365

15Ω

809

851

1489

2098

809

851

1489

2098

10Ω

645

1291

1744

645

1291

1744

6Ω

1105

1607

1105

1607

25Ω

208

524

950

208

524

950

21.5Ω

205

649

981

1953

205

649

981

1953

15Ω

300

332

1017

2019

300

332

1017

2019

10Ω

252

1008

1873

252

1008

1873

6Ω

940

1990

940

1990

25Ω

23%

24%

22%

23%

24%

22%

21.5Ω

23%

30%

23%

27%

23%

30%

23%

27%

15Ω

stall

15%

24%

27%

stall

15%

24%

27%

10Ω

stall

24%

25%

stall

24%

25%

6Ω

stall

27%

stall

27%

25Ω

278

441

595

278

441

595

21.5Ω

260

463

569

803

260

463

569

803

15Ω

275

289

506

712

275

289

506

712

10Ω

218

438

592

218

438

592

6Ω

375

546

375

546

25Ω

9.2

11.0

11.9

9.2

11.0

11.9

21.5Ω

8.7

11.6

11.4

16.1

8.7

11.6

11.4

16.1

15Ω

9.2

7.2

10.1

14.2

9.2

7.2

10.1

14.2

10Ω

5.5

8.8

11.8

5.5

8.8

11.8

6Ω

7.5

10.9

7.5

10.9