Wind Turbine Plans: Starting Guide

Generate Wind Turbine Airfoil Blade Cross-Sections

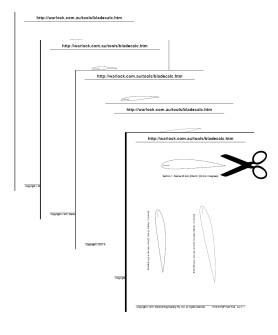

Generate Stencils For Your Airfoil Cross-Sections: Use the Chord Section Generator in the Trial Range for Free.

Starter Guide

Using the chord sections to manufacture wind turbine blades.

Free Trial: Cord Section Generator

How to use the pdf plans from the warlock blade design software.

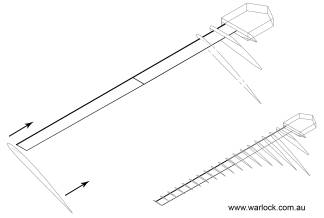

Custom chord sections outside this range can be purchased from $4.95, please send us your specifications. Follow the link below to order. Larger chord sections (beyond A0) may require up to 28 days for manuscript adjustment

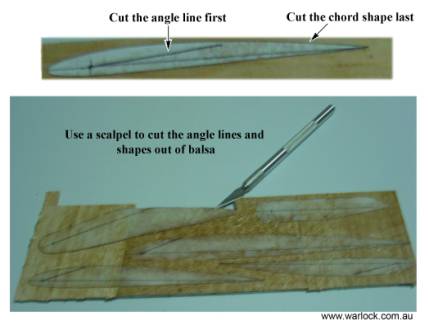

1. Print the bladecalc plans and cut out each chord section.

2. Paste the shapes on balsa (at least 3 mm thick (0.12 inch) and cover the entire piece with super-glue adhesive.

3. Cut out each balsa section using a scalpel.

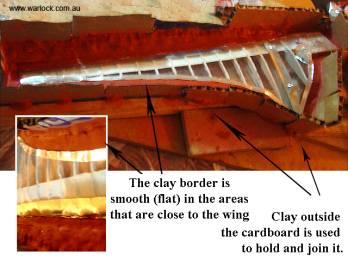

5. Create a root using a solid piece of plastic or sheet metal with a thin rod to align the crosshairs drawn on each section.

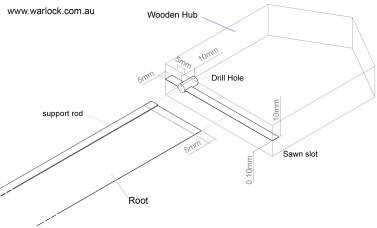

4. Make a hub from wood with a thickness to match section 1.

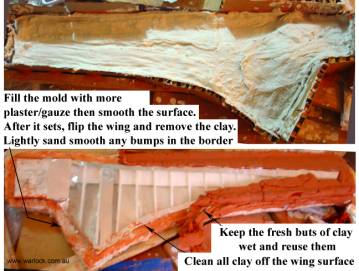

6. Glue the root into the hub.

7. Position each balsa section at the radius shown on the plans and glue (or silicon) them in place.

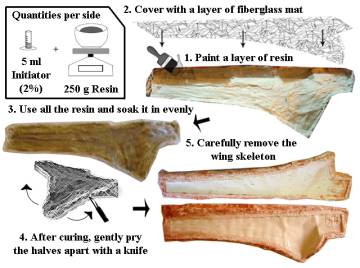

14. If the mold is too thin, fiberglass the outside of it before pulling it apart.

15. When dry, pull the mold apart and sand the insides smooth.

16. Apply a layer of wax to the inside of the mold. (Layers of hairspray or shellac also work)

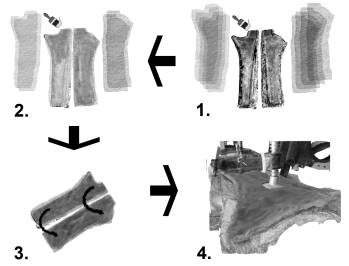

17. Fill the inside of both mold halves with at least 4 layers of fiberglass matting. For a 0.7 meter (2.30 ft) blade use at least 375g (13.23 Oz) of resin per side (steps 1-2).

18. Clamp both mold halves together when the resin has reached gel point (steps 3-4).

20. Sand the blade smooth and fit a solid hub piece.

19. After 72 hr, pull both halves of the mold apart. If a plaster mold sticks shut, the plaster can be dissolved with dilute vinegar or hydrochloric acid.

Frequently asked questions about plan orders, blade design, electrical work and generator matching can be found on our Q&A pages.

Free: Chord sections for 2 or 3 blade wind turbines with a radius between 0.70 and 0.80 meters (2.30 to 2.62 ft) at TSR 7 to 8.

Free plans for 500 W blades

with each purchase.

Design custom blades for your generator and calculate power output at each wind speed.

Free sample chord sections can be generated for 0.70 m to 0.80 m blades (550 Watts - 710 Watts).

SPONSORED ADVERTISEMENT

Design custom blades for your generator and

calculate power output at each wind speed.

Free sample chord sections can be generated for 0.70 m to 0.80 m blades (550 Watts - 710 Watts).

8. Use fiberglass gel-coat or epoxy to cover the entire blade skeleton.

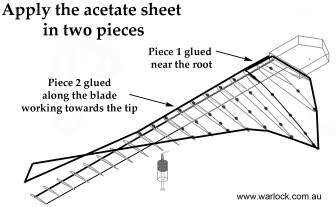

9. Glue acetate sheet to the top and bottom of the sections.

10. Seal the acetate sheet with aluminium tape (or waterproof tape).

11. Make a border to support the casting mixture. Molding clay is used for the border in this example.

The casting mixture we use here is plaster and gauze. Alternatives include plaster/fiberglass or fiberglass/fiberglass resin.

12. Fill the mold with the casting mixture and allow to dry for at least 48 hr.

Free sample chord sections available for blades between 0.70 m and 0.80 m.

Free plans for 500 W blades

with each purchase.

13. Make a cast of the other side.

500 W Turbine Plans

Included

With Your

Order

Included

With Your

Order

500 W Turbine Plans

Included

With Your

Order

Included

With Your

Order